Finally another blog post about the MattMobile! About frickin' time! For those of you who have not been following my exploits on Facebook or YouTube, I have been extremely busy with the work of film making. Been writing, executive producting, all kinds of stuff. Be sure to check out some of my recent blog posts for more details, especially for a link to Loadout!

First things first. Here's a look at the car in its current condition. You may be thinking "not much has changed!" You'd be right! 2014 was not a very good year for me as far as progress on the car goes. It was a GREAT year for me in regards to a number of other projects and personal accomplishments, but MattMobile progress was not one of them.

I got it in my head that what I really wanted to do was to rebuild the gun doors. I'm not sure what the builders club term is for these things, but these are the covers that go over the port that the big guns pop out of. In the movie, these doors are just ejected from the car, which I always thought was a really cool little piece of story telling. This picture shows what I'm talking about. You can see the big hole where the gun wold emerge from, and next to it is the cover. Like any kit, this shell needs some tlc in a few places, some more than others. The gun covers are probably the most desperately in need part of the entire build. I have seen other people try to straighten them, or reinforce them with steel, but I figured it would be a lot easier for me to just start from scratch. Oh, and that's a made-for-production DareDevil billy club sitting on the car too. No biggie.

I started off by measuring the opening, and made a few adjustments accordingly. I wanted to make sure the new doors would fit, but would also have an even gap running around the entire edge. I began by measuring a large rectangle on a piece of 1/4 inch MDF. I drew in a few different lines, so that I could use my poor-man's table saw technique, which I have discussed in previous posts.

The thing that's great about this technique is that I can be extremely precise. A table saw typically proves to be problematic when it comes to keeping everything aligned and spaced perfectly. Using my method, I clamp a piece of aluminum stock to the wood, one inch from where I want to cut. My rotary saw has a one inch guide on it, so I line up the guide with the aluminum, and I get nice straight cuts every time.

Here's the piece cut to the correct length and width.

And here is the cut piece in comparison to the door from the kit that I am trying to recreate.

Now it's time to start working on the curves. I don't have a compass big enough to draw a half circle in the diameter I need, so I had to improvise. I took a piece of styrene, and measured out the desired radius I wanted for my arc. I used one point to locate a push pin, which serves as an anchor. I put the tip of my pencil in the other hole. I then stick the pin in the MDF, right in the middle of it, and then just draw out the arc.

Here's what it looks like all drawn out and pretty. It's not 100% precise, but it's close enough for my purposes.

I then use a coping saw to cut out the general shape. I don't try to get too close to the lines, as that's when errors happen. I'd much rather cut wide, then end up doing a llittle extra sanding. The other option is to accidentally cut too deep, and then have to putty and sand. Which I hate.

I use a piece of scrap wood with some sand paper stuck to it as my sandin block. This allows me to shape the arc into what I want it to be.

The next step was to work on the arcs on the read corners. I experimented a few times with the radius until I got it right. I tested my measurements using the same scrap piece of styrene. This time I was able to use my compass to draw the arcs.

And it was then a simple matter to transfer them to the MDF. you can see where I drew lines on the MDF so that I could locate the center point to my circle.

Using the same technique for finishing out the arc using the coping saw and my sanding block, the rear corners now look like this.

I didn't take any pictures of the process of drawing out these shapes, but it was very similar to the process I've already described in this post. I used a piece of styrene scrap for the main circle, then a compass for the smaller circles. A coping saw cut out the main shapes, then sanding paper and some files were used to get them to where I need them to be.

I thought long and hard about how to get the louvers onto my new master. I originally planned to cut all of them off, and then transplant them onto my new pattern. That seemed a little destructive, and in looking at the louvers, they are all asymmetric and need some attention. I figured, rather than clean up a bunch of them and then transplant, how about I clean up one of them, mold it, then pour up six copies and attach those to my new master. And a new plan was born! I started by hitting the first one with a couple coats of primer, so that I could reveal the flaws in it.

Then I went in with some spot putty and filled in the more aggregious offenders.

Some sanding and another coat of primer later, and one of my louvers is ready to be duplicated.

That about wraps it up for progress on the gun well covers for today. I left the project alone so that the paint could dry overnight. Molding on the louver will be the first thing I do upon return to my shop.

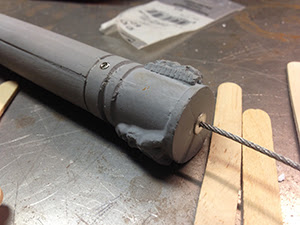

Another task I wanted to attend to was making the airbag hoses fit properly. As build the hoses get smushed in the only opening on the back spring housings. I don't even know if that is the right term, but whatever. My plan to fix this involves three steps. First is modifying the mount on the airbag so that the hose is free to go straight up, rather than have to snake around a bit to get out of the opening in it's current position. After some fun with the reciprocating saw and the drill press, I came up with this. Not exactly elegant, but fully functional.

Step two is to drill a hole in the spring housing that is big enough to fit the hose.

Here you can see both of the bags are installed, with the hoses now coming out of the housing unhindered. This will stop the hoses from getting worn any time the bags are inflated or deflated. They shift a little in their resting positions, causing the hoses to get cut up. I don't want that to happen.

The third step, which I have not yet completed, is to drill a new hold in the mag mount plate which will allow me to bolt the plate to the spring housing. That will stop the airbag from spinning or moving at all, thus insuring that the hoses are in no danger of getting sliced up.

Lastly, Bo The Welder was on hand tonight to do some work on the electrical harness on the Harley. Lots of progresss. It's really coming along now.